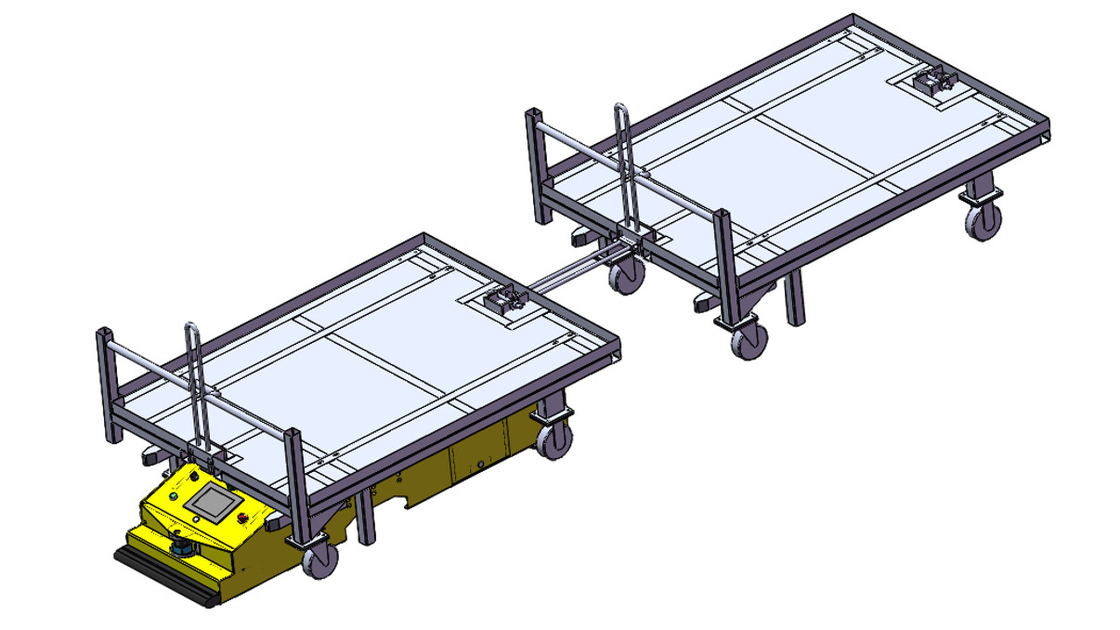

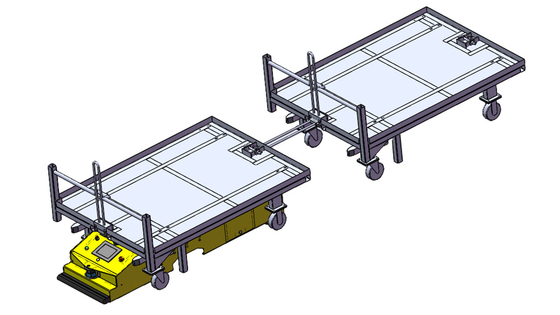

Bidirectional 600kg AGV Autonomous Guided Vehicles Self Guided Vehicles

-

High Light

600kg AGV Autonomous Guided Vehicles

,AGV Autonomous Guided Vehicles

,600kg self guided vehicles

-

Core ComponentsPLC, Motor

-

ApplicationMaterial Handling

-

DimensionL1875*W580*H350

-

Payload600kg

-

MovementBidirectional

-

MaterialStainless Steel

-

Weight (KG)250

-

CertificatesCE

-

Place of OriginGuangzhou, China

-

Brand NameZHLUN

-

CertificationISO9001

-

Model NumberZL-TR-K1

-

Minimum Order QuantityNegotiable

-

PriceNegotiable

-

Packaging DetailsPacking: Wooden Box

-

Delivery Time25 days

-

Payment TermsL/C, T/T, Western Union

-

Supply Ability1000 Pieces per Month

Bidirectional 600kg AGV Autonomous Guided Vehicles Self Guided Vehicles

AGV Logitech Driving Wheel Automatic Guide Vehicle Warehouse Agv For Industry

The AGV is a standard gauge, high-speed, electric multiple-unit train designed and built by Alstom. Alstom offers the AGV in configurations from seven to fourteen carriages, seating 245 to 446 persons. The trains are constructed from units comprising three cars and single-car driver-trailers. The maximum commercial speed is 360 km/h.

![]()

The application of AGV trolleys in manufacturing factories is becoming more and more common. It can realize unmanned handling, and realize the automation of automatic on-line, automatic off-line, and midway transfer from products to materials, which is a good solution to improve the efficiency of production logistics. In the manufacturing process of manufacturing, cross-floor transportation is often carried out, which is also achievable for AGV. At present, the more powerful AGV manufacturers can achieve automatic transportation across floors. The difficulty of AGV's cross-floor transportation is to solve the technology of AGV trolleys automatically ride elevators.

How does the AGV car take the elevator automatically?

The process of the AGV car taking the elevator automatically is divided into the following steps:

![]()

1. The AGV car arrives at the elevator door and stops, and the AGV control system sends an elevator entry request instruction to the elevator through the network.

2. After the elevator receives the signal from the AGV control system, it opens the door and maintains the normally open state. And feedback the signal that the elevator has been opened to the AGV control system.

3. After receiving the signal that the elevator has been opened, the AGV control system issues a driving instruction to the AGV trolley, and the AGV trolley enters the elevator.

4. After the AGV car enters the elevator, it sends a floor instruction to the elevator. The elevator receives the instruction, closes the elevator, and arrives at the designated floor.

5. After the elevator reaches the designated floor, the elevator door opens and keeps the normally open state. And send the elevator door normally open signal to the AGV control system.

6. After the AGV control system receives the arrival at the designated floor, it sends a driving instruction to the AGV trolley, and the AGV trolley uses the elevator.

7. After the AGV trolley exits the elevator, the AGV control system feeds back a signal to the elevator, the elevator door is closed, and the next cycle is entered.

In the whole process, we can understand it as the interaction between the AGV car, the AGV dispatching management system, and the intelligent elevator. It includes the interaction between the AGV car and the AGV dispatching management system through the wireless network and the AGV dispatching management system and information exchange between the elevators.

![]()

Here is mainly to share with you the AGV system and elevator interaction process: AGV applies for elevator registration → elevator feedback registration is successful → AGV queries elevator floor → elevator feedback floor → AGV requests elevator door → elevator door hold → AGV enters / exits elevator → AGV Stop sending door opening request → elevator door closing → elevator release successfully.

With the improvement of AGV technology, the application scenarios of AGV will be further expanded. In the future, AGV trolleys will be more able to adapt to complex work scenarios such as multiple obstacles, cross floors, and cluttered warehouses, and can more ensure the safety, stability, reliability and orderliness of the logistics handling process.

|

Item

|

Specifications

|

|

Model

|

ZL-TR-K1 |

|

Dimensions

|

L1875*W580*H350

|

|

Guide method

|

Magnetic navigation

|

|

Walking direction

|

Forward,Steer,back

|

|

Forward speed

|

90m/min

|

|

Carrying capacity

|

600Kg

|

|

Battery

|

Lithium battery

|

|

Charging method

|

Wireless charge

|

|

The way of electrical display

|

Electronic display

|

|

Safety sensing distance

|

3m

|

|

Alarm form

|

Music alarm and light alarm

|

|

Power system

|

BLDC motor

|

|

Security system

|

Infrared obstacle avoidance, mechanical anti-collision design, emergency stop button

|

Factory Picture

![]()

![]()

![]()